scratch test alternative uniaxial compression|The Scratch Test: An Attractive Technique for : discounter Help | OnePetro Help and FAQs User Guides OnePetro User guide (pdf . 19 de nov. de 2019 · Identifier. undertheboardwalkmerge1. Scanner. Internet Archive HTML5 Uploader 1.6.4. 1,661 Views. 4. on November 19, 2019. It is the final weekend of summer .

{plog:ftitle_list}

WEBCruz Fox Official. Tiffany Mantovani ,cruz fox Richard castro. 37.4k 85% 5min - 1080p.

The Scratch Test is a quasi-non-destructive method made up of pushing a tool across the surface of a weaker rock at a given penetration depth. The Uniaxial Compression Test is a destructive method of measuring the maximum axial compressive stress a rock can .The Scratch Test is a quasi-non-destructive method made up of pushing a tool .

Help | OnePetro Help and FAQs User Guides OnePetro User guide (pdf . The scratch test is thus an attractive and elegant alternative to conventional uniaxial compression tests and to indirect methods such as the point load test and the Schmidt .

The uniaxial or unconfined compressive rock strength (\ ( {\text {UCS}}\)) which is the ultimate stress a rock can withstand before undergoing failure, is characterized by rock . The present study provides a review of the test methods for measurement of the UCS, including the laboratory/in situ uniaxial compression tests and 17 indirect test .

Previous studies have shown the scratch test method to be reproducible, non-destructive, and faster in juxtaposition to the “conventional” uniaxial compression test method, . The uniaxial compressive strength (UCS) is the most common measure of strength used in civil, mining, and petroleum engineering, with applications ranging from the .

For that reason, an innovative purely mechanical test setup is proposed in this article, which eliminates the identified confounding effects. Furthermore, an alternative procedure for the investigation of rock dilatancy .

The Scratch Test method provides a micro-scale and localized measurement of unconfined compressive strength (UCS) along the samples, whereas the Uniaxial . The uniaxial compressive strength (UCS) of rocks is a vital geomechanical parameter widely used for rock mass classification, stability analysis, and engineering design in rock engineering.. In this study, we presented the application of the scratch test to measure uniaxial compressive strength within the ductile scratch regime and opening mode fracture toughness . The uniaxial compression test used to determine the UCS suffers from several drawbacks, however. . Alternative indirect methods to estimate the UCS, such as the point load test, the indentation test, or the Schmidt hammer test, have been developed over the years (Broch and Franklin, 1972, Bieniawski, 1974, Bieniawski, 1975, Chau and Wong .

2.1 Rock Materials. Two types of limestone—Savonnières (SL) and Tuffeau (TL)—were investigated. Conventional methods proposed by Bieniawski and Bernede and Kuruppu et al. were used to measure uniaxial compressive strength σ c and the opening mode fracture toughness K IC, respectively.Six specimens were tested for each rock, three for σ c .

Digital Plastic and Rubber Thickness Meter distributor

Uniaxial Compression Testing

Uniaxial compression strength (UCS) is a fundamental parameter to carry out geotechnical engineering design and construction. It is simple and efficient to predict UCS using point load strength (PLS) at engineering sites. . Unlike triaxial and uniaxial compression test, scratch test is able to measure UCS of the acid fracture asperities. Compared with hardness test, scratch test can obtain more strength values from the same sample, thus avoiding the inaccurate results concluded by hardness test due to few hardness data points and sampling bias.

This study investigated the impact of inherent heterogeneity on the measurement of continuous micromechanical and macromechanical properties of shale reservoirs using scratch test (ST) and uniaxial compression test (UCT) methods, and the degree of correlation (correlation coefficient, r) of measurements in shale was further assessed for the .The scratch test is thus an attractive and elegant alternative to conventional uniaxial compression tests and to indirect methods such as the point load test and the Schmidt hammer test. Acknowledgment Many people have contributed to the development of the scratch test to measure the strength of rocks and to the design of the RSD. For unconfined but also triaxial compression tests, the alternative technique is to measure strains directly at the specimen, via extensometers or strain gauges. . Contrary to uniaxial compression tests or compression tests at low confining pressure, . regardless of whether uniaxial or triaxial compression test, direct or indirect tension .

The contribution is focused on investigation of strains in a rock specimen during uniaxial compression test. Three components of strain occur in cylindrical shape specimen: axial, radial and .

As for the scratch test, a work piece of size 51.42 × 36 . the material initially experiences pure compression, and at this stage, the scratch force increases monotonically. . A strong anisotropy was seen from the MD simulations of tensile and scratching testing on HEA in terms of uniaxial tensile stress, scratch force, kinetic coefficient . In order to estimate the UCS for this oil field, three methods were applied: the standard uniaxial test, the scratch test and a log-based correlation. Due to the excellent agreement among results of all three methods, it was possible to extrapolate the data regarding UCS for the entire interval to be analyzed. The set of logs available, mainly . Different possibilities such as existence of defects, pores and micro-cracks in the rock specimen have been attributed as the cause of axial splitting in the literature. Based on some physical uniaxial compression tests on Pennsylvania blue sandstone, an alternative theory for axial splitting is proposed.

DOI: 10.1016/j.rockmb.2023.100065 Corpus ID: 260104883; Assessment of inherent heterogeneity effect on continuous mechanical properties of shale via uniaxial compression and scratch test methods To this purpose, the hypothesis was tested through virtual experiments in which a numerical simulation of a uniaxial compression test with a cylindrical, rock-like sample was created to mimic the .

The uniaxial compression test is a destructive, time-consuming, and expensive test. Some of the research works that adopted uniaxial compression test to measure and estimate the mechanical .

Uniaxial Compression Test Uniaxial compression test is one of the popular test which is done in rock mechanic laboratories. Although this test is very simple, but it’s has many application in rock problems. 2 Effective parameter on UCS Internal parameters mineralogy density porosityUniaxial compression test (UCS) is one of the oldest and simplest rock mechanical test used to determine the Young’s modulus and unconfined compressive strength. It is also used as the most common simulation to .

The Scratch Test: An Attractive Technique for

The Uniaxial Compression Test, or also uniaxial test or simply uniaxial test, is a test that allows to characterize the strength of a rock and is standardized according to the ASTM-D7012 standard. The uniaxial compression test .This study investigated the impact of inherent heterogeneity on the measurement of continuous micromechanical and macromechanical properties of shale reservoirs using scratch test (ST) and uniaxial compression test (UCT) methods, and the degree of correlation (correlation coefficient, r) of measurements in shale was further assessed for the . The failure process is violent in the uniaxial compression test under axial strain control mode. In order to protect the extensometer from damage, only the uniaxial compression tests under lateral .

The uniaxial compressive strength (UCS) test is crucial in determining the strength and stiffness behavior of intact rock and is frequently utilized by industry to determine project site characteristics. A fundamental procedure of UCS testing is strain response measurement. Conventionally, discrete strain measuring devices such as extensometers and/or electric foil .The properties of the uniaxial test will be discussed first, before considering triaxial and other multiaxial loading cases. In its simplest form, the uniaxial compression test is conducted by taking a right cylinder of intact rock, loading it along its axis and recording the displacement produced as the force is increased.Caractérisation de la résistance à la compression simple des roches par deux techniques différentes: Essai Uniaxial et Scratch Test . Approche compression simple-scratch test --- 25 1.7.4. Conclusion --- 27 CHAPITRE 2 : Techniques expérimentales et procédures d'essais 2.1.Introduction: --- 28 The rock mechanics’ test system of TAW-3000 is used for the test. The uniaxial compression test is performed with displacement loading in the direction parallel to the longest size of the specimen and applied at a loading rate of 0.002 mm/s. At the beginning of the experiment, the loading system and the high-speed camera are running .

In this study, the challenges associated with conducting high-strain rate uniaxial compression testing experiments are highlighted. To address these challenges, DEFORM-3D simulation was explored as an alternative approach to experimental testing. Previously established constitutive constants obtained from experimental low strain rate uniaxial . The scratch test is a quasi-non-destructive method, was developed [1, 2] over 2 decades ago, made up of pushing a tool across the surface of a weaker rock and tracing the groove at a given penetration depth.The uniaxial or unconfined compressive rock strength (\({\text{UCS}}\)) which is the ultimate stress a rock can withstand before undergoing failure, is . 2.3 Uniaxial Compression Granite Specimen Test. Uniaxial compression tests are carried out on laser-irradiated rock specimens as shown in Fig. 3. The main cylinder at the lower end of the uniaxial compression testing machine can apply a maximum static load of 1050 kN. Before the test, applies lubricant to the end surface of the specimen to .

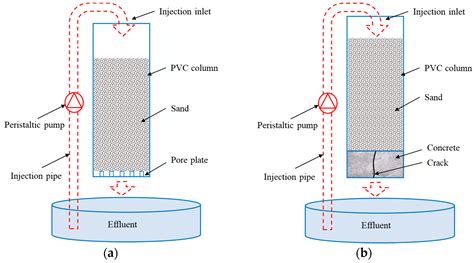

In this paper, based on the experimental result of closed fractured rock, combined with the results of nuclear magnetic resonance, the variation of porosity before and after the test of closed fractured rock is compared and analyzed. At the same time, the numerical model of closed fractured rock with different dip angles is established by using the Particle flow code, .

Pipe wall Thickness Meter distributor

webGrátis. Oferece compras dentro do app. Capturas de tela. iPad. iPhone. Jogo de fusão de frutas fofas! Combine frutas fofas para criar frutas maiores! Quem consegue criar .

scratch test alternative uniaxial compression|The Scratch Test: An Attractive Technique for